Your CNC Woodworking Specialist

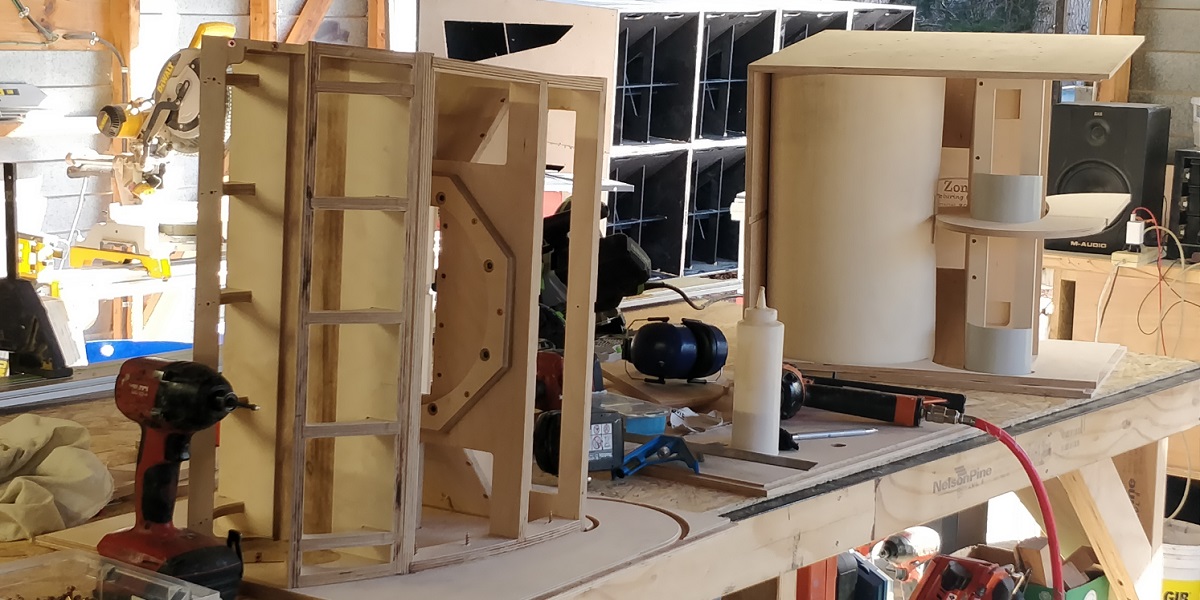

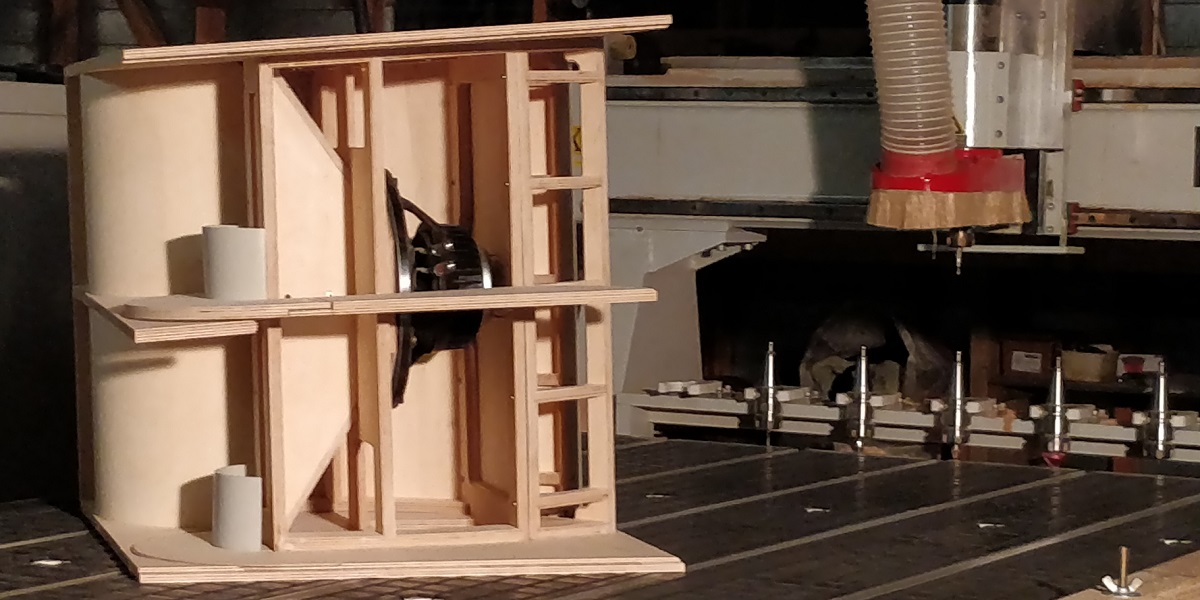

We specialize in Computer Aided Design (3D Modelling) and shaping of wooden parts for small to large production runs and sometimes even one off jobs. We use CNC machines that Automate the process to ensure precision, repeatability and the economies of scale. We love to fine tune the process at every opportunity to increase the quality, efficiency and of course to cut perfect parts for our customers. We can also engrave signs & logos including laser engraving for finer details. If you are thinking of creating a wooden product or simply need some tricky or repetitive shapes cut we would love to talk with you about your project and offer our services if they suit your needs.

3D Modeling, Computer Aided Design or CAD

All projects begin with an idea & some kind of concept sketch. Usually this is what our customers bring forth, along with a discussion about how they are ready for the next step of having the idea modeled in a CAD software for use in the digital manufacturing process. Sometimes people already have a CAD model and want to get straight to chatting about cutting their parts using a CNC machine.

What is CNC Machining?

CNC stands for “Computer Numerical Control” which really means any machine controlled by a computer generated code known as “G-Code”. Even a standard desktop printer is a CNC machine, therefore across industry there are many different types of CNC machines for many different purposes. Here at Zone 2 we have 2 CNC routers which are mainly used for cutting wood, plastics, foams, composites and non ferrous metals. We also have a Laser engraver that we use for adding logo’s onto the finished products.

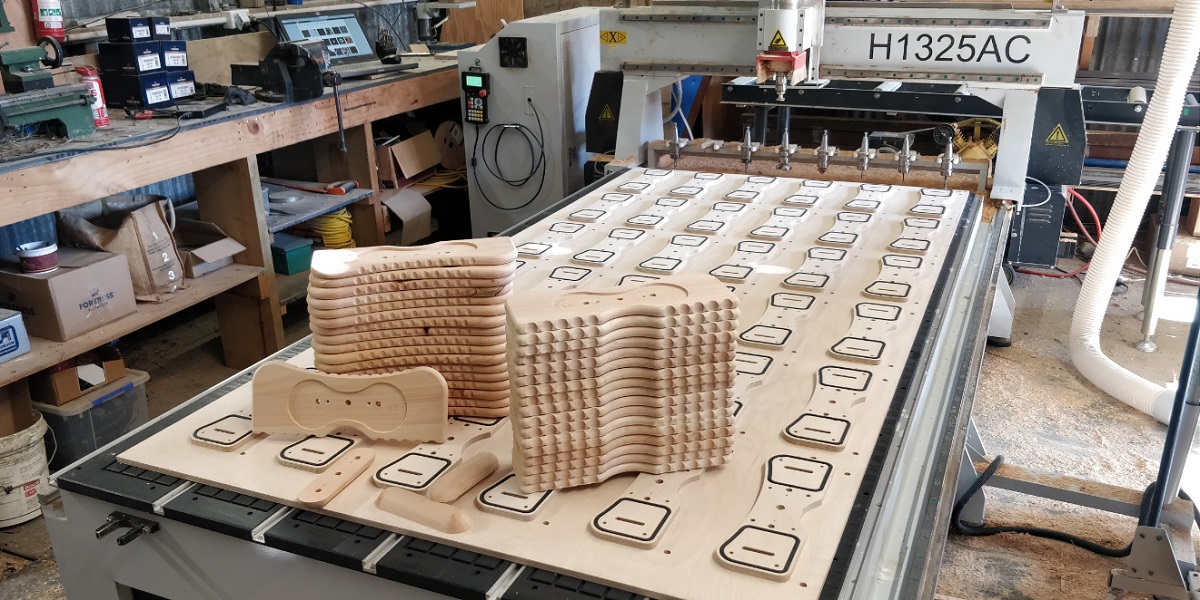

Nesting, Duplicating & Tool pathing

At this point we have a computer model of the part (or parts) we are trying to create and it is likely that the customer wants to cut more than one of them. Because that’s where CNC machining really pays off, with precision & repeatability. So we duplicate the part (or dis-assemble the 3d model of “parts”) and spread the pieces out virtually inside the material that we will be cutting the parts from. This is called “nesting”. We then add the the toolpaths to the nested 3D model. The “toolpath” is the route that the tool takes to cut the features and perimeter of the part. Different features require different cutting strategies with different depths, speeds, feeds & tooling. So this is a vital part of the CNC machining process and is referred to as CAM in the industry (Computer Aided Machining). We just call it programming.

Stock Simulation

last but not least we run a stock simulation of the CNC machine doing it’s job to check that everything is cool and there are no un foreseen collisions before we cut real material. Now we are ready to generate the “G-code”, turning our toolpaths into coordinate instructions that the CNC machine understands. The “G-Code” is really the Computer Numerical Control or “CNC”.

CNC Router specifications

- Bed/ max job dimensions: 2500L x 1300W x 250H mm.

- 3 axis router with an automatic tool changer and an 8 tool magazine. This means we can automate all your hole drilling, corner rounding, engraving, chamfer, boring and slotting requirements.

- The vacuum bed really speeds things up saving time on clamping and enables the use of full sheets of material.

Choosing & Ordering Your Material

We can help to order the special materials for your job from our trade suppliers, but will require full payment upfront including shipping before confirming the order. Deposits and material on the shelf is the best way to secure your place in line for our services.

We can provide samples and prices for a vast range of materials on request & can lend you sample packs while you choose your colors.

[email protected]

[email protected]027 4260 440